For optimum forming of thin-walled micro-perforated metal foils, the embossing pattern and an additional pre-forming process may be of high importance.

PEC2TEC has all the necessary capabilities to process the pre-forming of semi-finished metal foils, reliably, on time, and according to the highest quality standards.

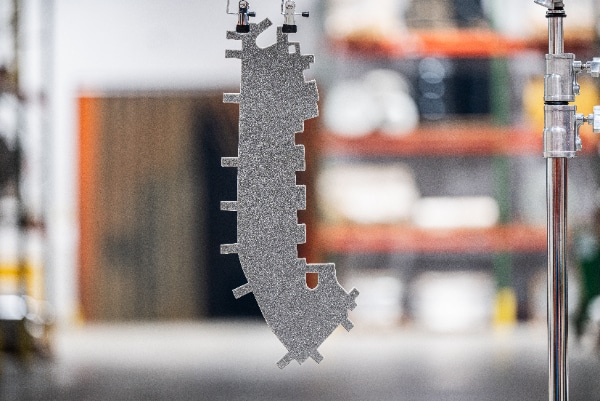

Do you have specific requirements on the outer shape? Smooth and embossed foils can be die-cut up to a maximum size of 54” x 55” (1380 mm x 1400 mm).

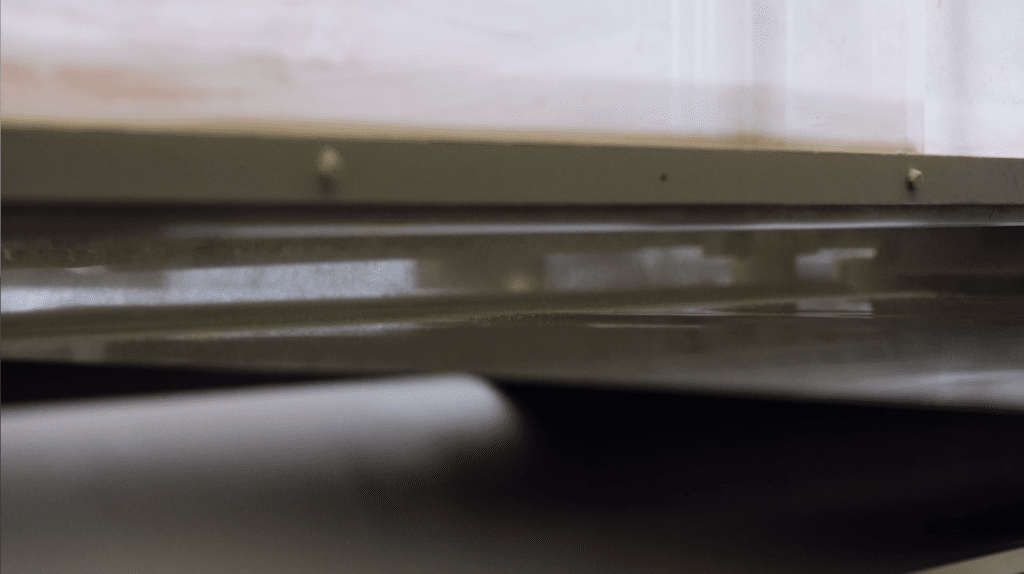

In 2018 PEC2TEC developed a non-toxic adhesive Polypropylene ( PP ) film and a PUR ( Thermoset Polyurethane Resin ) based powder adhesive to replace the toxic solvent that is used in the metal foils industry for coating applications.

These advancements not only create a better product, but because of PEC2TEC's unique coating technology, the PEC2TEC facility is now 100% emissions-free.

Additionally, the new film and powder dramatically reduce waste since there is no trim that needs to be removed.

The PEC2TEC coating is applied to one side of the aluminum to best suit the customer's process when bonding our aluminum to their nonwoven fabric or substrate of their choice.

To make the next processing steps in our customer´s facilities easier, we can provide embossed material being cut to the requested size. Our high precision longitudinal and cross cutting systems process blanks with outer dimensions up to 55” x 354” (1400 mm x 9000 mm).

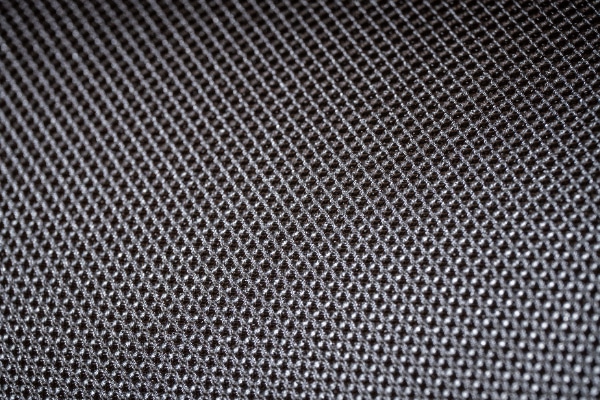

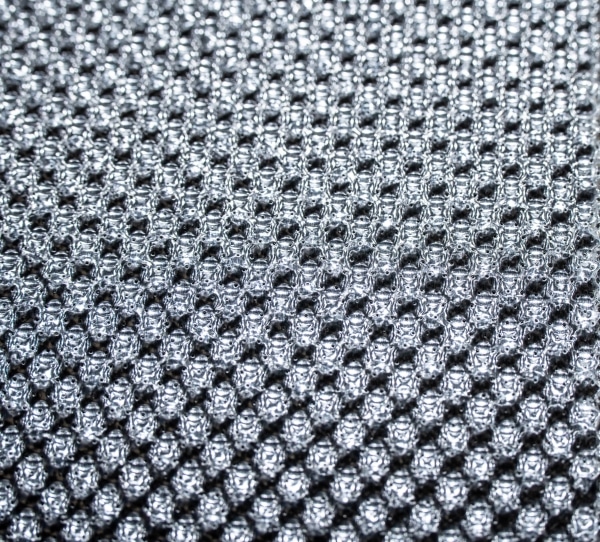

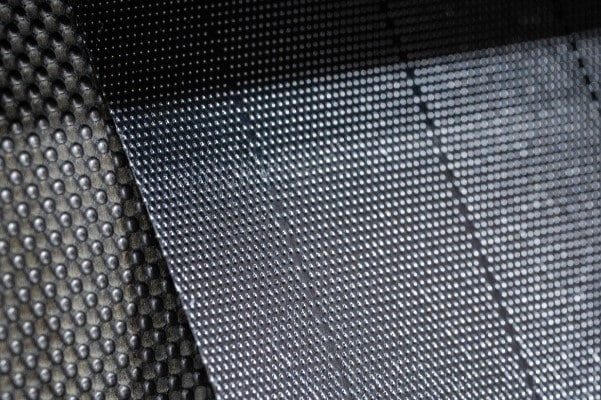

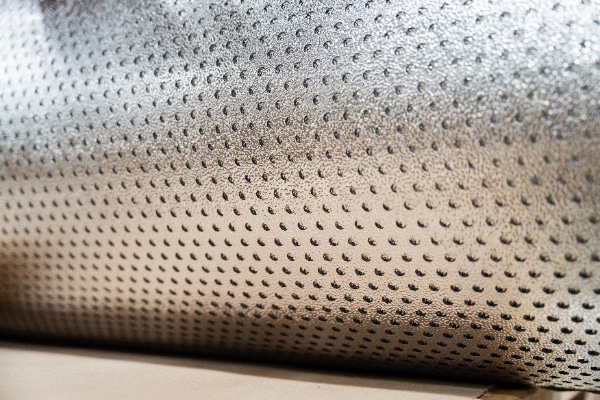

Our embossing process is tooled to produce three types of embossing, either large ball calotte or small ball calotte up to a coil width of 55 “(1400 mm) and stucco embossing. Our state-of-the-art embossing calendars are designed to optimize machine output while securing process quality.

With our manufacturing lines, we produce various micro-perforation patterns, ranging from 32 holes / in² to 320 holes / in² (5 holes/cm² to 50 holes/cm²). We are currently tooled to produce 32 holes / in² and 154 holes / in². All perforated materials can be embossed and processed to customer requirements.

We at PEC2TEC keep a large stock of metal foils, which enables us to supply our customers with a high degree of flexibility. We concentrate on industrial metal foil applications, processing aluminum and stainless-steel foils as a semi-finished product adding features as they are needed for high-performance thermal and acoustic insulation products in the automotive industry.

The combination of heat-reflecting material properties with the sound-absorbing function of micro-perforation has made our products become a key component for modern thermal and acoustic insulating automotive components.

Founded in 2014, PEC2TEC Corporation is an experienced, and innovative company serving the American markets with micro-perforated, embossed top-quality metal foils and metal products.